Flaps have become ubiquitous on modern airplanes, as they give pilots more flexibility and maneuverability during landing and, occasionally, takeoff.

The purpose of flaps is to create both extra lift and drag, lift being created by increasing the surface area of the wing, and drag by extending the flap down into the air stream.

This allows pilots to increase their angle of descent, while maintaining the same airspeed.

It also allows pilots to decrease their ground roll, shortening the runway needed to land.

Sometimes flaps are used during takeoff, where they use their extra lift and drag to get the plane in the air more quickly, shortening the amount of runway required.

There are 4 main types of flaps, and this article will focus on Fowler Flaps.

What exactly are Fowler Flaps, and what sets them apart from other types of flaps? You will find the answers below!

Related Article – Aircraft Altimeters Explained

1. What is a Fowler Flap?

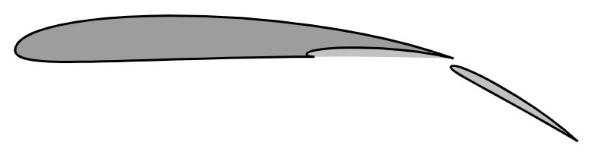

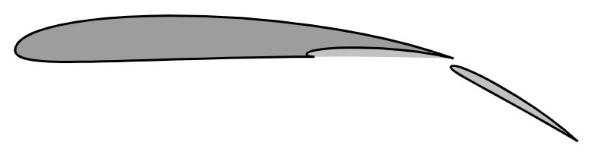

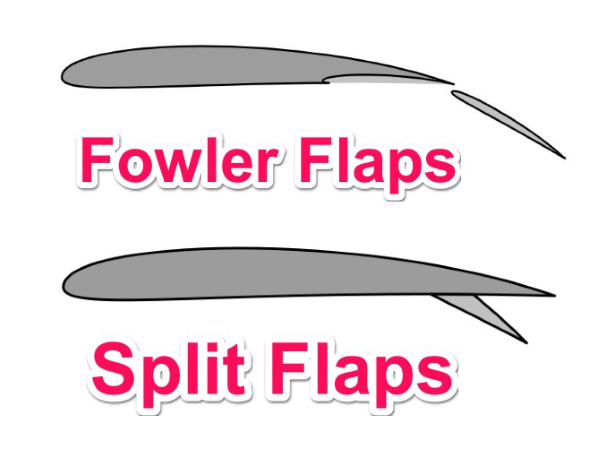

Fowler flaps are unique in that they combine two movements together, sliding backwards before downward rotation.

Sliding the flap backwards increases the surface area of the wing, resulting in increased lift.

The downward rotation increases drag, as well as increasing the wing cord and camber.

Because the flap is separate from the rest of the wing, it inherently has at least one, sometimes several, slots in between the flap and the wing.

The slot(s) take some high-velocity air from the bottom of the wing and re-directs it to the top of the flap, preventing airflow separation and increasing efficiency.

2. History of the Fowler Flap

The Fowler Flap was patented by Harlan D. Fowler, an early American aircraft engineer, in 1921.

Originally an idea for a variable-area wing, he self-funded and developed the Fowler Flap in 1927.

He forwarded his design to Fred Weick of the National Advisory Committee for Aeronautics (NACA), who saw the potential of Fowler’s design.

In 1929, Fowler started his own business, Fowler Airplane Wings, Inc., in hopes of marketing and further developing his design. The arrival of the Great Depression slowed down development, however.

The first large airplane to use the Fowler Flap was the Martin Model 146 prototype, developed from the Martin B-10, for a medium bomber design competition in 1934.

Although losing the competition to the B-18, the promise of the Fowler Flap led to it being used on other contemporary aircraft, such as the Lockheed Super Electra, in 1937.

Related Article – Class G Airspace Explained

3. What types of aircraft use Fowler Flaps?

First used on interwar airplanes, Fowler Flaps saw use on famous and successful WWII airplanes, notably the B-17 Flying Fortress, B-29 Stratofortress, and the P-38 Lightning.

Due to its versatility in increasing wing area and lift, Fowler Flaps today are used on many large airliners and cargo planes, such as the Boeing 747, among others.

4. Fowler Flaps vs. Slotted Flaps

As previously stated, Fowler Flaps are inherently slotted, the slot allowing high velocity airflow from the lower portion of the wing to flow over the lowered portion of the flap.

Slotted Flaps are similar to Conventional Flaps in that they use a simple hinged rotation of the wing.

Slotted Flaps, however, are set rearward, with a gap in-between it and the wing.

The purpose of the gap in between the wing and the flap is for the extra airflow, but it doesn’t allow for rearward movement and the resultant increase in wing surface area.

Slotted Flaps are less complicated to implement and therefore weigh less than Fowler Flaps, but increase efficiency over Conventional Flaps.

5. Fowler Flaps vs. Split Flaps

With Split Flaps, only the lower part of the rearward portion of the wing is rotated downward.

Because the top part of the wing remains intact, there is no slotted effect, and the wing curvature is unaffected, in contrast to Fowler Flaps.

Split Flaps create a bit more lift than standard flaps, but also create drag similar to standard flaps.

Split Flaps were developed by Orville Wright, father of powered flight, in 1920.

However, because Slotted Flaps and Fowler Flaps came out shortly after Split Flaps and were more efficient, Split Flaps were phased out shortly after their adoption.

You can see many planes today with Split Flaps at your local Warbird airshow.

Related Article – Turbojet vs. Turbofan: 3 Differences (and similarities) of Each

Conclusion

The development of flaps was an important part of overall aircraft development in the 20th century.

Finding a way to increase the angle of descent during landing while also decreasing the landing and takeoff rolls was paramount. Flaps were developed to address this problem.

Conventional and Split Flaps were initially conceived, being simple hinged mechanisms that achieved the goals of the engineers.

However, as airplanes became bigger, with higher performance, more efficient ways were developed to slow planes down during landing, and to increase lift during takeoff.

The most efficient flap design in common usage today is the Fowler Flap, using rearward movement to increase wing surface area, and downward rotation to increase drag.

Due to its design, Fowler Flaps include slots as well, which feeds high speed air from the bottom portion of the wings and redirects it to the top portion of the flap.

This minimizes airflow separation, increasing efficiency.

While more complicated than other solutions, the Fowler Flap is the best of both worlds, combining high lift and drag, which is necessary for today’s high performance aircraft.

References